Injection Molding

Proudly Producing Sustainable, Fiber reinforced pellets for Injection Molding to Manufacture Strong Plastic Parts.

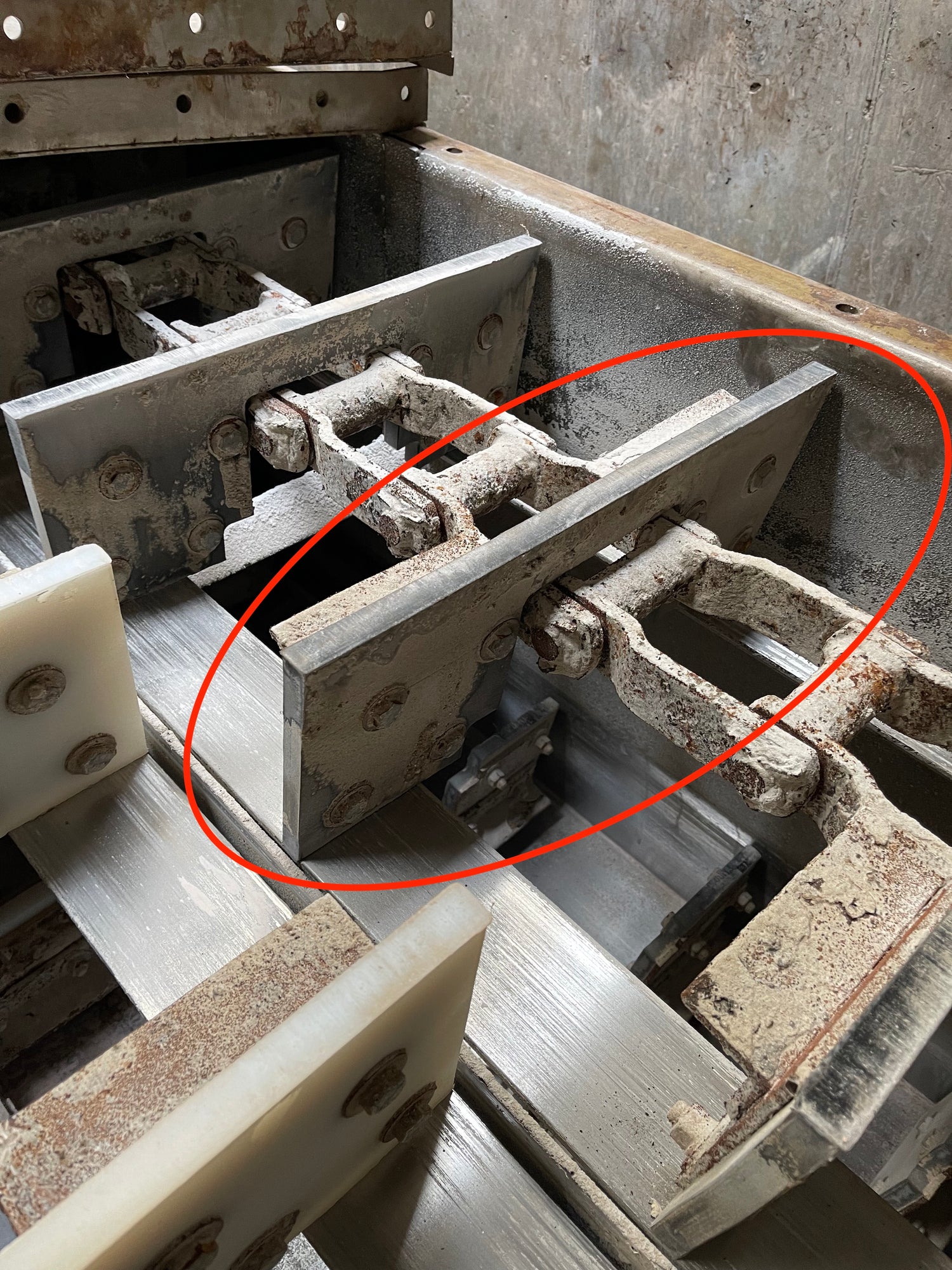

Ultra High Molecular Weight Polyethylene

Proudly Manufacturing Sustainable UHMWPE Parts for Use in Various Industries

FAQS

Q - How are your raw materials different?

A. We use our patented and proprietary processes to reinforce thermoplastics with our recycled carbon fiber.

Q - Is your Carbon fiber recovery an energy intensive process?

A. Our process for fiber recovery is performed under ambient conditions. This allows us to preserve the integrity of the fibers and significantly reduce the energy use when compared to manufacturing new carbon fiber.

Q - Do we need new tooling and machinery to process carbon fiber filled plastics for Injection Molding?

A. No, our materials have been proved to be "drop-in" materials. You can use existing tools and machinery to process our carbon reinforced plastics.

Q -Can your carbon fiber be used to make any plastic stronger?

A. Our carbon fiber is resin agnostic so we can reinforce most thermoplastics.

Q - What is the increase in product performance we can expect?

A. We formulate our materials specific to the part requirements. Parts made with our materials have been proven to last up to 3X longer.

Q - Do we need to switch suppliers to be able to use your materials?

A. No. We can work with your existing suppliers.

Q - Can you produce plastic parts per our requirements?

A. Yes, we have expert manufacturing partners who we work with and can manufacture parts per your requirements.